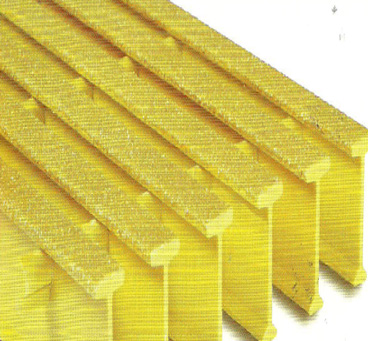

The strength and corrosion resistance of FRP grating are related to the glass content, resin content, resin type and method of construction. EFG molded products provide an outstanding balance of corrosion resistance, slip resistance and strength.

In EFG, this advanced grating is manufactured with a recessed tie bar configuration and is lightweight and easy to fabricate. It is used in a wide range of industrial applications that require strength and corrosion resistance. It provides durability, extremely high unidirectional strength and stiffness.

Eissa Fiber glass lining is being recommended by Consultants for Godowns, Tanks, Mild Steel Containers, and Pipe Lines etc for the following reasons Weather Proofing Protection from humidity, moisture, fungi, insects & bacterial growth and biological degradation in the container. It does not rust, rot, corrode or swell. Extra Thermal and Electrical insulation and fire resistance can be incorporated, if required. Resins are also available to suit lining for storage of Food, Oils, Petroleum and Strong Chemicals. Fullest utilization of space and no chance of spillage, leakage or any sort of wastage of stored material. Longer life of lining and stored items is guaranteed by virtue of resin quality. Ease of Maintenance, Cleaning and Repair Normally the lining consists of two layers of chopped mat hardened with Polyester Resin followed by a thick layer of Gel coat giving a thickness of approx. 2.5mm. Thickness can be varied as per specifications subject to the quality and life of protection required. The materials used namely resin and fiberglass mat are the most advanced in today’s technology and imported from only reputed manufactures all over the world.

In EFG, different types of resins are used for the manufacturing of RTRP (Reinforced Thermosetting Resin Pipes), which are selected according to the required properties like chemical resistance, temperature resistance and mechanical properties. The properties of FRP (Fiberglass Reinforced Plastic Pipes) can be varied by changing the ratio of the raw materials. Glass fibers provide strength and stiffness to a composite material. According to the type of resin used, FRP pipes can be classified as; GRP - Glass Reinforced Polyester (Iso-phallic resin) GRV - Glass Reinforced Vinyl ester (Vinyl ester resin) GRE - Glass Reinforced Epoxy (Epoxy resin)

This is a restrained joint system used for joining plain end pipes which consists of overlapping layers of fiberglass reinforcement thoroughly impregnated with the resin to achieve the specified width and thickness. It provides continuity in both hoop and axial directions. It is generally preferred for field adjustments and repair work where no other joint systems can be used. This joint is also called butt and strap joint and it results in high strength and requires skilled labor. Once the core pipe is laminated and tested successfully, jacket pipe cut to exact length to fit in the joint area is installed. This jacket pipe piece is laminated with the main jacket pipe by the same procedure. A nozzle is made on the jacket pipe to carry out the air test and subsequent injection of poly urethane foam. This type of joint is applicable for all the available pipe sizes.